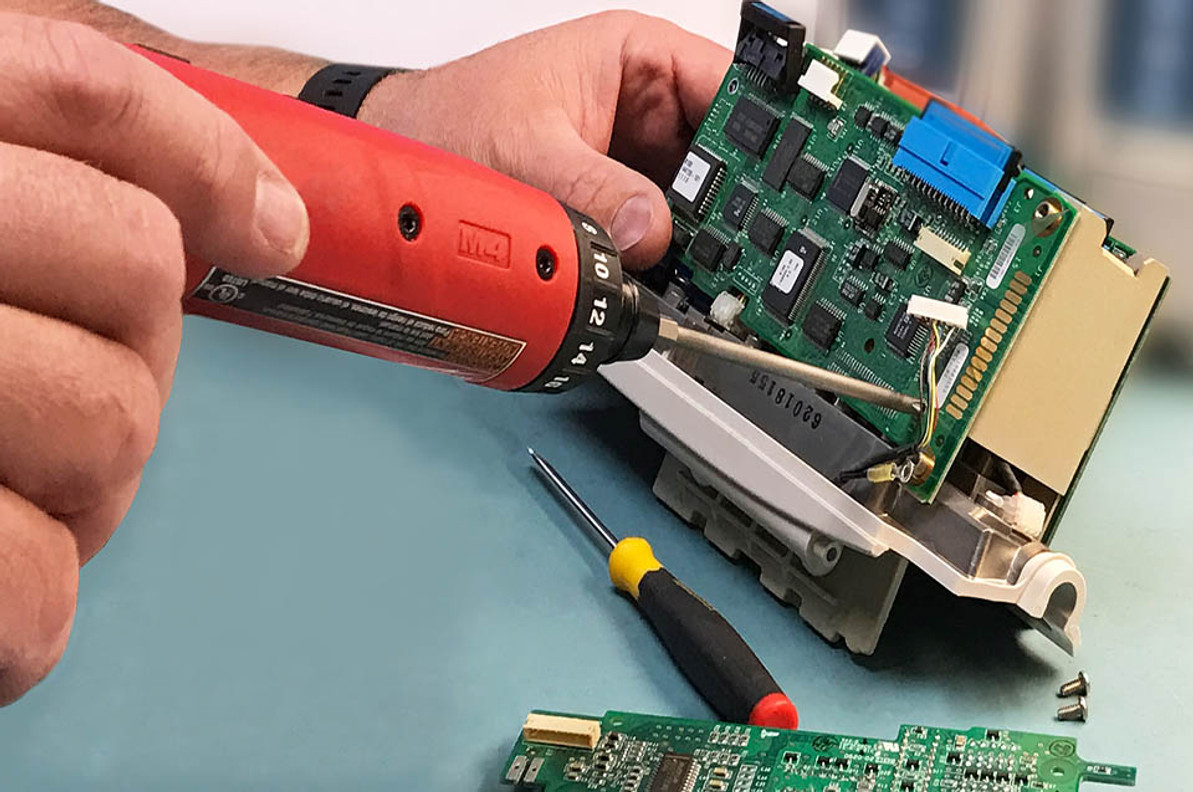

Refurbishment Testing Process

The refurbishment process for Jaken Medical varies for each piece of equipment that we receive in our inventory. Being that we are ISO 9001 certified, our process has been approved as one that is effective, efficient, and overall satisfying to the customer. The one common denominator for all of our testing procedures is consistency. At Jaken Medical, we consistently test each product as well as the last, and we never undervalue a machine without thorough examination.

EKG/ECG Machines:

The refurbishment process for EKG/ECG machines first begins with an initial inspection. One of our biomedical technicians will review the EKG/ECG system and go through a checkout procedure. In this stage of inspection, we put the machine through a series of tests, such as a power-up self-test, data storage/saving test, dust/debris blowout, and many more. These tests help the biomedical technician decide which parts of the machine are running strong and which parts may need more attention.

The next stage of the reconditioning process for EKG/ECG systems is the electrical safety checks. Some settings we check during this process include earth leakage, enclosure leakage, and patient leakage. Each setting is reviewed both with neutral and ground open. Lastly in our EKG/ECG machine refurbishment process is the cycle testing. We test the machine through ten regular EKG and ten rhythm strip cycles in order to make sure the machine is running properly throughout various cycles of function.

Patient Monitors:

Our reconditioning process for patient monitors begins with an initial inspection from one of our biomedical technicians. The technician will then begin a checkout procedure, which will include various testing such as a power-up self-test, network connectivity, and dust/debris blowout.

There are several other tests involved in this portion of the refurbishment process for patient monitors to ensure that the monitor is running properly in all aspects of its functionality. The machine is then put under electrical safety checks, where it is tested for earth leakage, enclosure leakage, and patient leakage. Each of these tests are performed with neutral and ground open. Lastly, the patient monitor undergoes a set of cycle testing to make sure that it can function properly throughout numerous sequences of procedure.

Ultrasound:

The Jaken Medical reconditioning method for ultrasound systems will include an initial inspection and testing of various attributes of the ultrasound machine. The PW, CW, color, and power dopplers are all thoroughly tested and inspected by our biomedical technicians. Other features of the ultrasound, such as harmonic imaging, articulation arm, and probe connectors, are also carefully examined. Every single function on the ultrasound machine is examined and tested with the utmost attention to minor detail. For non-portable ultrasound machines, we test the applications with extreme precision.

Stress-Treadmills:

Upon receiving stress-treadmills in need of refurbishment, our service technicians will inspect the excess wear and visual signs of damage in the work surface, handrails, shroud, and walking belt. The reconditioning process can include a variety of tune-ups, some including replacement of bearings in the rollers or motor, refinishing or replacing the walking deck or belt, refinishing handrails, etc.

We also make sure to perform self-calibration tests on the equipment to further analyze the equipment’s functionality. An electrical safety check is performed in order to specify the requirements on each machine’s ground wire leakage and chassis leakage to ground. After these tests are performed and the stress-treadmill is fully reviewed and fixed, we make sure to give each machine a proper cleaning. The work surface, handrails, shroud, and walking belt are all appropriately cleaned and lubricated with wax, grease, or oil on all moving components.

Stress Controllers:

The refurbishment process for stress controllers, like all other products here at Jaken Medical, includes an initial inspection. If necessary, we will replace the CR232 and clean the motherboard. Next, we check to see if the controller may need a new harddrive, image hd, software, etc. Jaken Medical service technicians will refurbish/replace any parts necessary on the stress controller before undergoing calibration/testing for the unit. Testing includes performing a burn-in test and testing the acquisition module/treadmill communication. Each level of the Jaken Medical refurbishment process for stress controllers is thoroughly documented and recorded for our and the customer’s awareness.

Conclusion:

As one can see, there are rigorous testing procedures with a large attention to detail that goes into our refurbishment process for cardiology diagnostic equipment. Jaken Medical is constantly seeking to improve these processes in order to better deliver overall customer satisfaction.

Recent Posts

-

A New Look at PAD: September is Peripheral Artery Disease Awareness Month

A New Look at PAD: September is Peripheral Artery Disease Awareness Month It's that time of year aga …Sep 3rd 2025 -

Service & Repair

We offer a wide range of service and repair options: standard on-site repair, depot repair (mail-in) …Mar 3rd 2025 -

Love Your Heart: February is American Heart Month!

February is American Heart Month, a time dedicated to raising awareness about heart health and encou …Feb 18th 2025